Exhaust Heat Recovery System

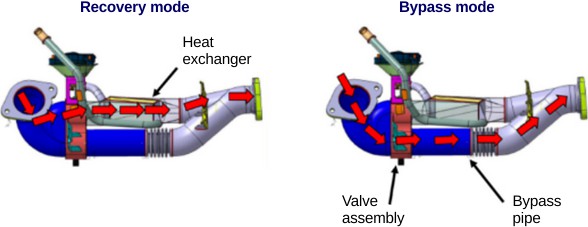

Exhaust heat recovery system. These products recover this heat energy improving the vehicles cabin heating function and contributing to improved fuel consumption levels by warming up the engine faster. Hot exhaust gases from boilers dryers ovens or other processes can be used to heat incoming air or gas streams required by the process. BorgWarners exhaust heat recovery systems transfer the heat that would normally go out the exhaust pipe to the vehicles coolant fluid to reduce the warm-up phase of the engine and increase passenger comfort.

Through recovering the heat air energy at the level of the exhaust fan this system drastically reduces the energy load for the air renewal. Compared to the conventional type the 4th generation heat collectors are 60 smaller in size and 41 lighter in weight yet maintains a fuel. Find out information about exhaust-heat recovery system.

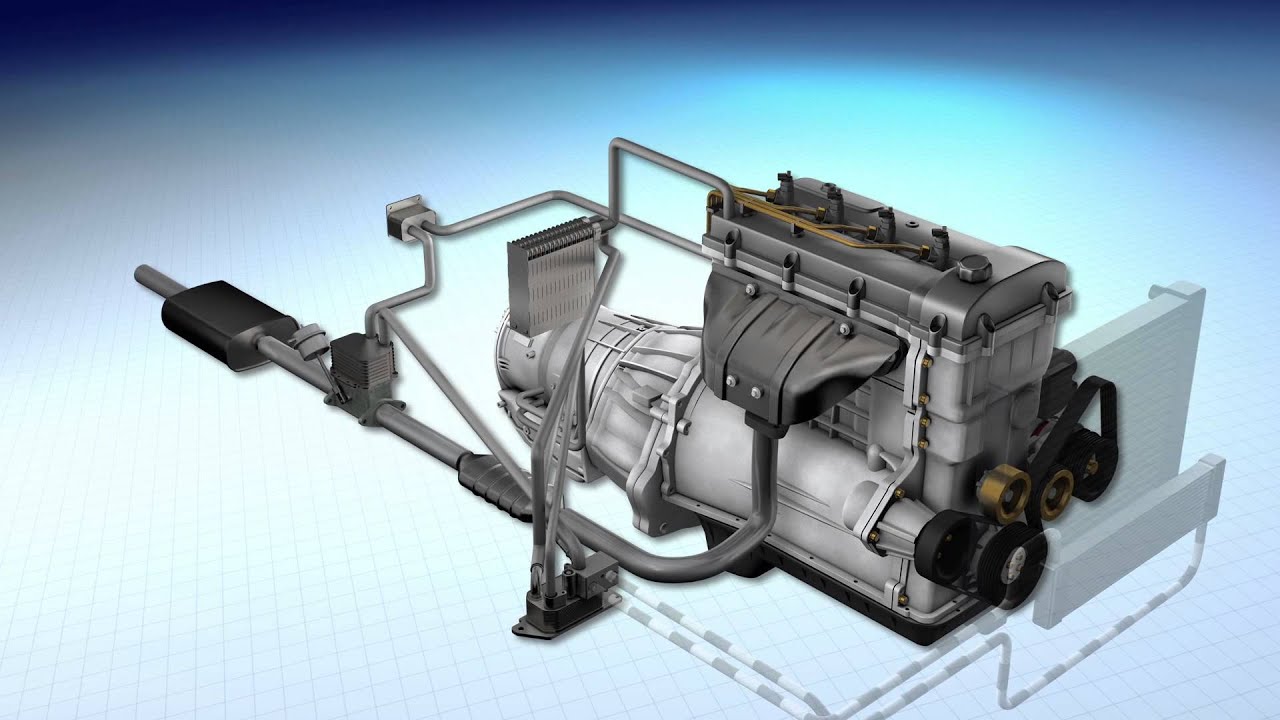

With the upcoming new emissions regulations cold-start will have a big impact on the overall homologation cycles where both emissions and fuel consumption a. Of all the heat recovery systems heat pipes are the lowest maintenance. Although not technically an engine component or function waste heat recovery systems attempt to regain some of the 50 or so lost thermal efficiency from the fuel used in the engine.

Exhaust Heat Recovery Systems Energy recovery is a key player when it comes to increasing the efficiency of combustion and hybrid vehicles. The team incorporated a high-performance networked run-around heat-recovery-coil loop system along with indirect adiabaticevaporative cooling of exhaust air. Exhaust Heat Recovery From A Mobile Power Generation System is an invention by Jeffrey G.

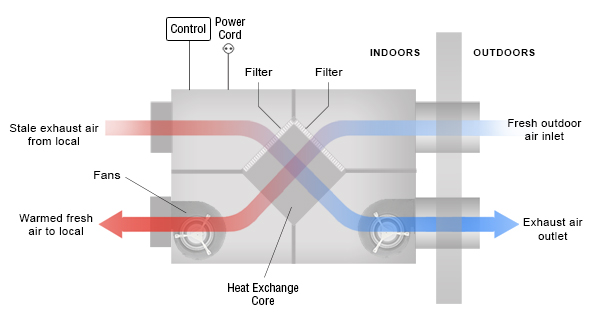

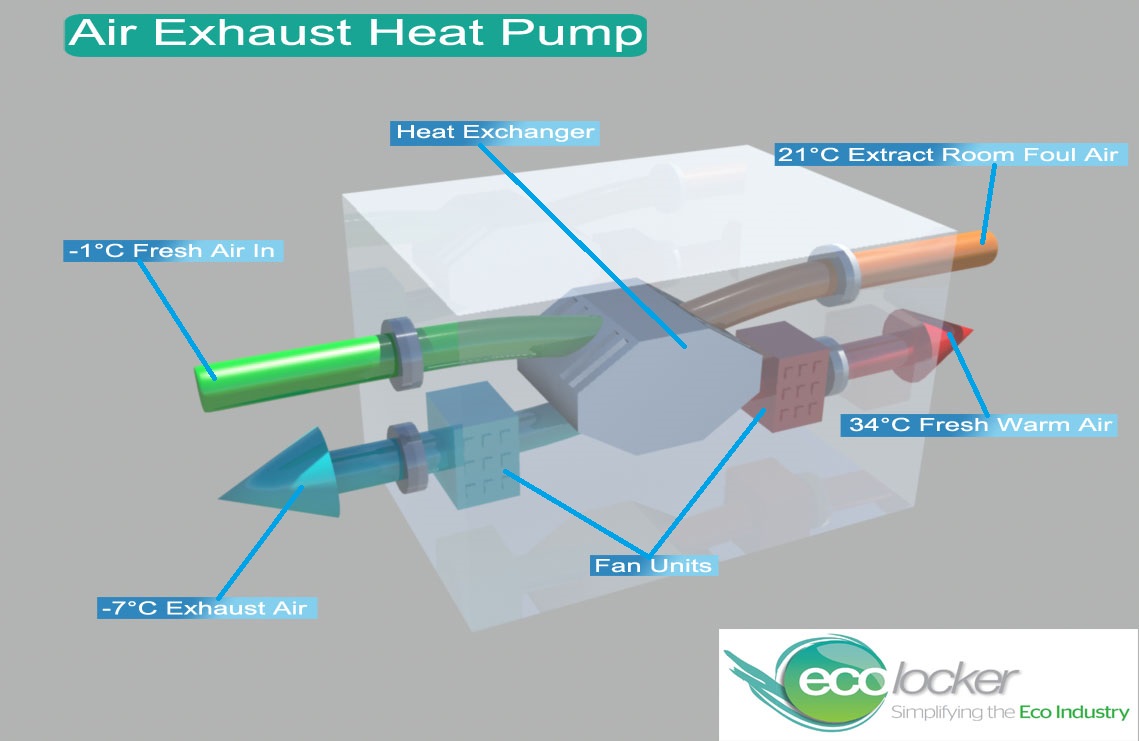

It uses a tube system with a refrigerant to extract the heat from the exhaust air and pass it to the supply air. Comfort or Space Heating. Water glycol or refrigerant.

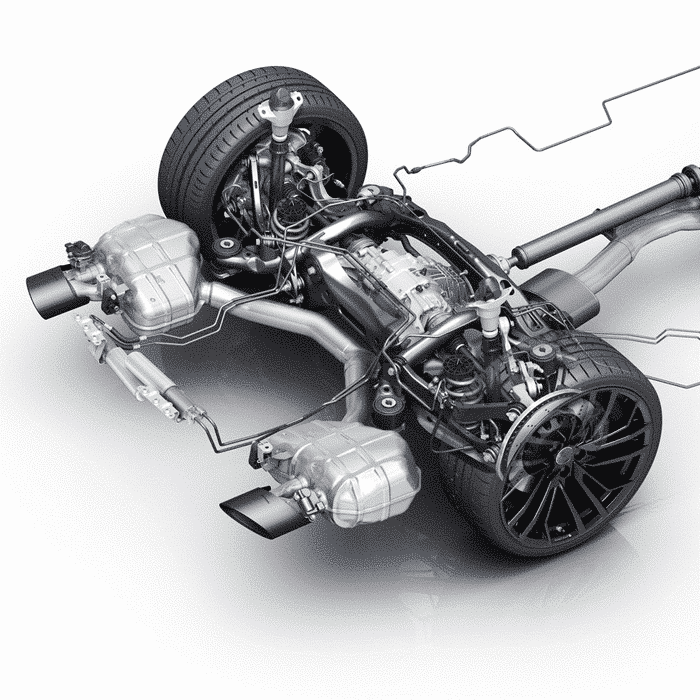

Waste heat recovery systems are more sophisticated than the simple exhaust gas boiler or economizer and the heat can be used in variety of ways. The AWN range of fans offers two types of calorigen fluid. The heat which is unused by the engine is in turn used to heat the vehicle fluids such as engine oil engine coolant and.

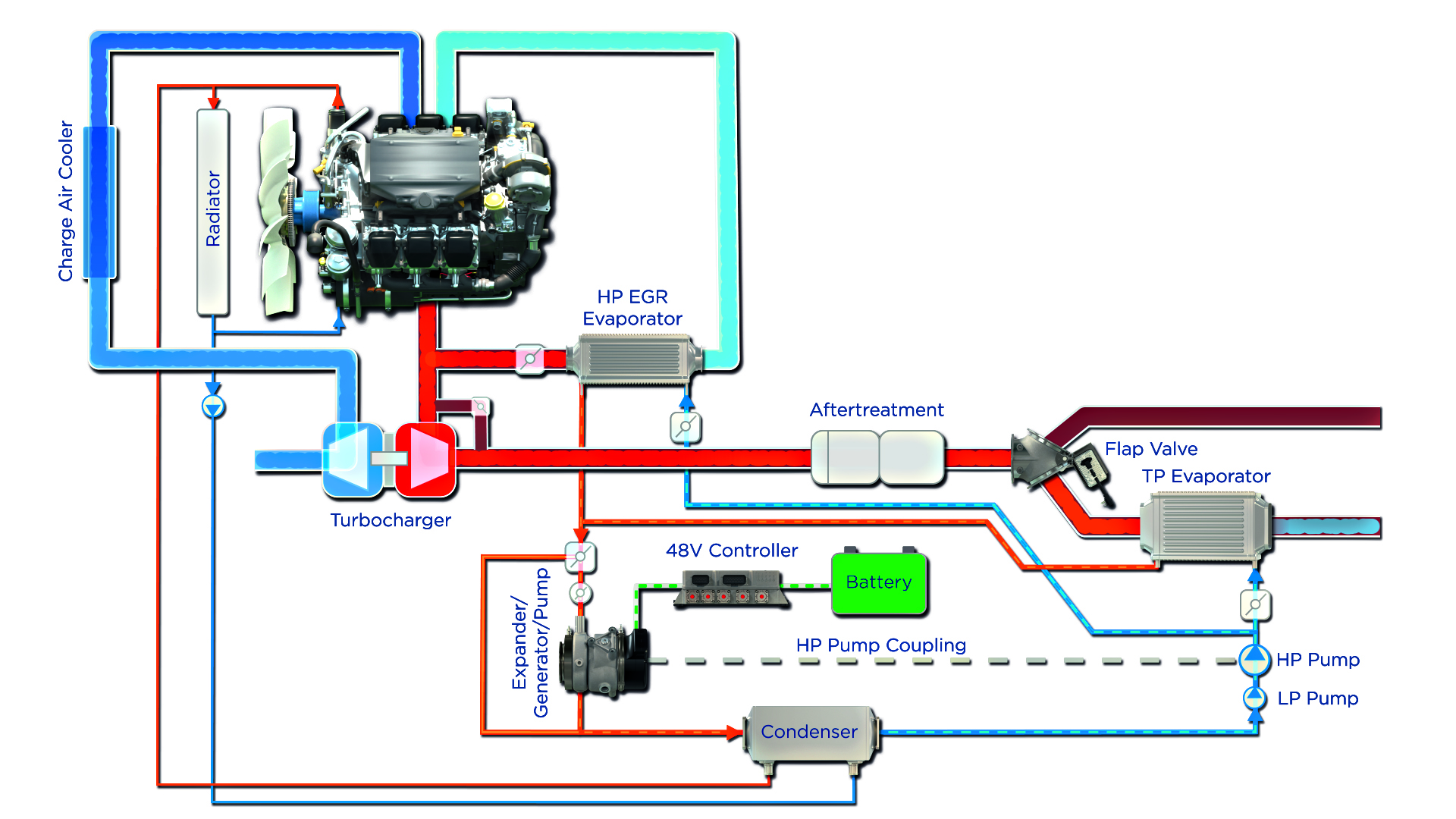

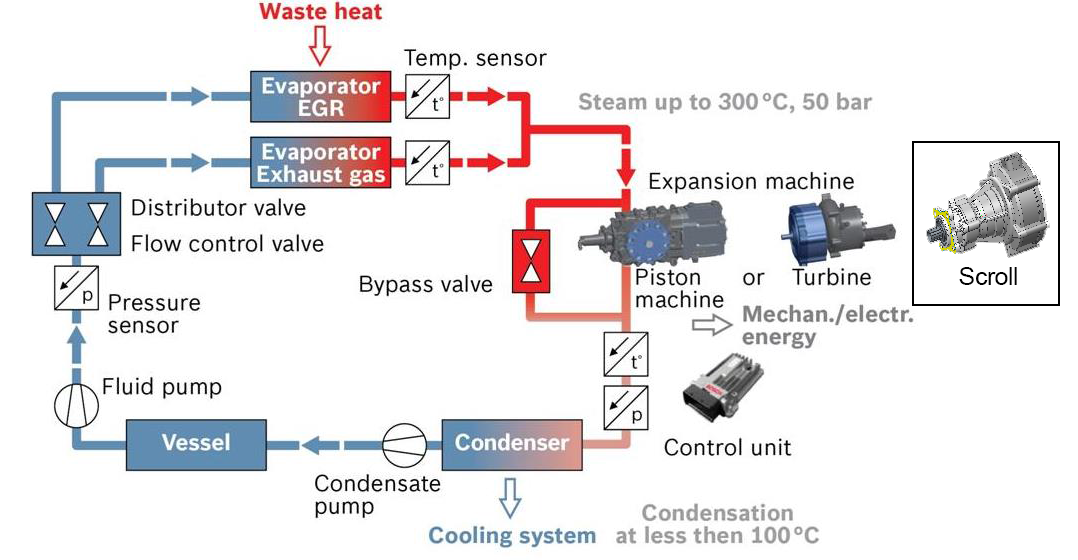

Diesel and Gas Cogeneration Boiler Exhaust Economizers and Fume Incineration. 4 illustrates an actual ORC-based exhaust heat recovery system which is mounted on the exhaust pipe downstream of the supercharger or downstream of the after-treatment system if there is.

Compared to the conventional type the 4th generation heat collectors are 60 smaller in size and 41 lighter in weight yet maintains a fuel.

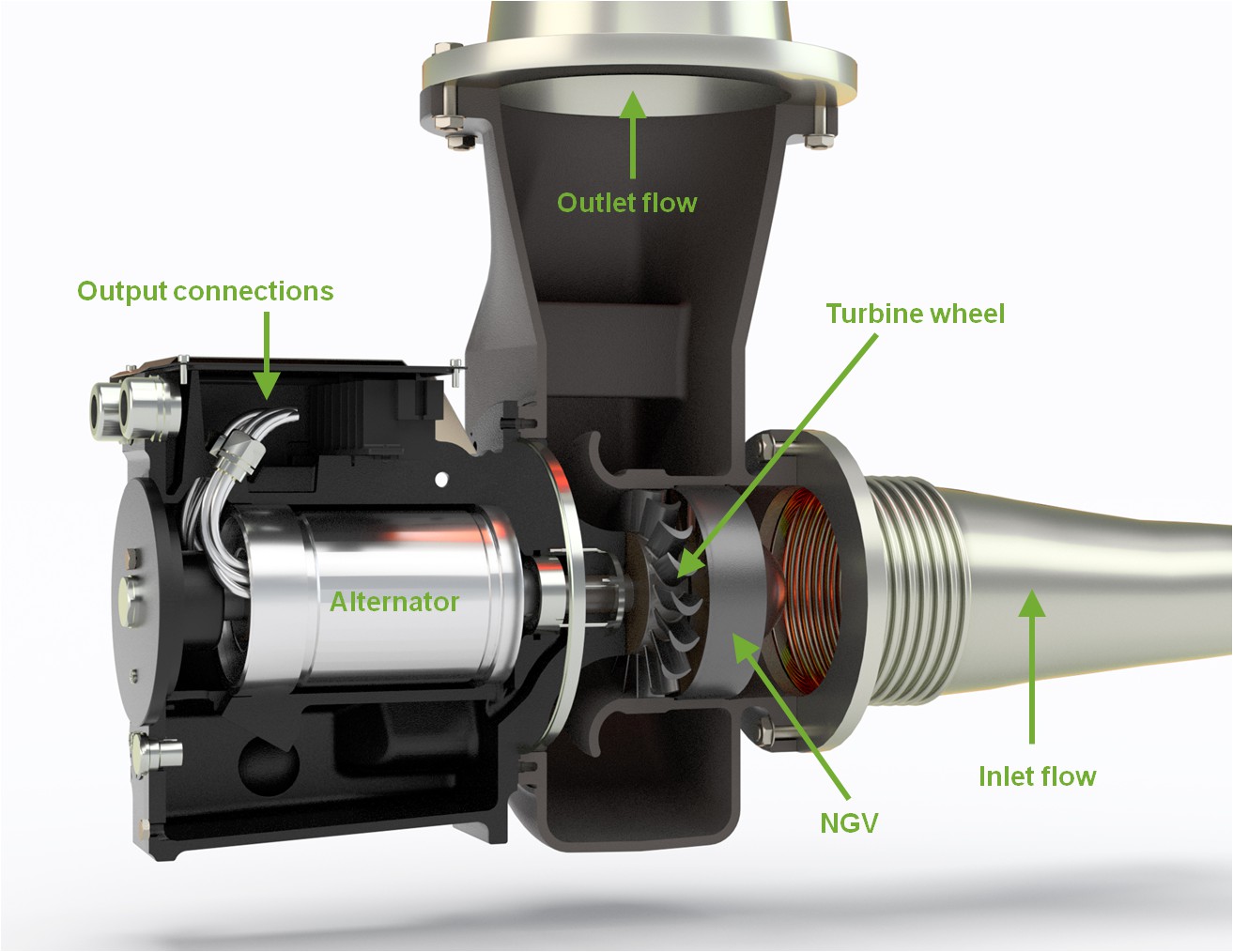

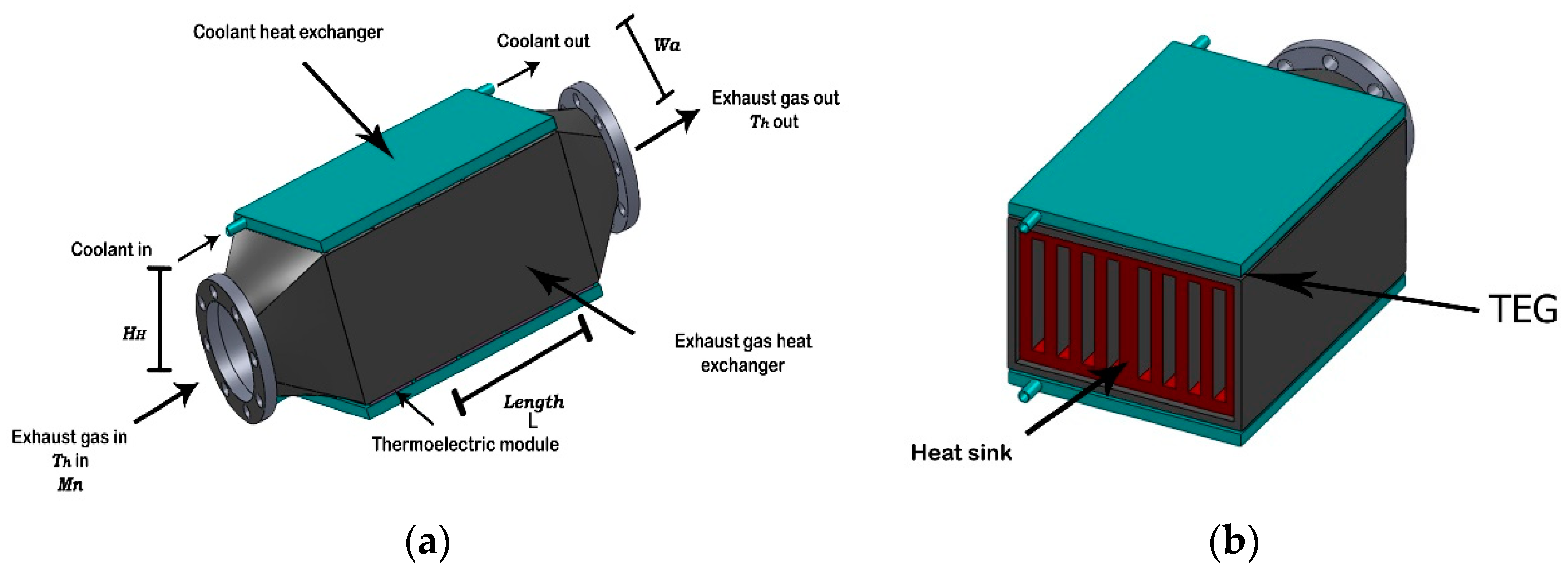

The Rankine Cycle makes use of the phase change characteristics of. The AWN fan with heat recovery is connected to a heat pump that can be used for water heating or air heating. The team incorporated a high-performance networked run-around heat-recovery-coil loop system along with indirect adiabaticevaporative cooling of exhaust air. Exhaust Heat Recovery Systems Energy recovery is a key player when it comes to increasing the efficiency of combustion and hybrid vehicles. Heat Energy Recovery Audits. An Exhaust Heat Recovery System converts waste heat energy from exhaust gases into either electric energy for batteries or mechanical energy for the crankshaft. With the upcoming new emissions regulations cold-start will have a big impact on the overall homologation cycles where both emissions and fuel consumption a. The Rankine Cycle makes use of the phase change characteristics of. Exhaust Heat Recovery Systems.

Heat recovery system is used for pre-conditioning the fresh air by using the energy of the exhaust air by reducing the enthalpy of fresh air in summer time. The AWN range of fans offers two types of calorigen fluid. The use of waste heat in a building to preheat cold water before it is fed into a hot-water heater. Find out information about exhaust-heat recovery system. Heat collectors exhaust heat recovery device Heat from combustion in the engine is expelled in the exhaust gas. Through recovering the heat air energy at the level of the exhaust fan this system drastically reduces the energy load for the air renewal. Economizers installed in a boilers flue gas to preheat the boiler feedwater.

Post a Comment for "Exhaust Heat Recovery System"